A Better World

Starts With You . . .

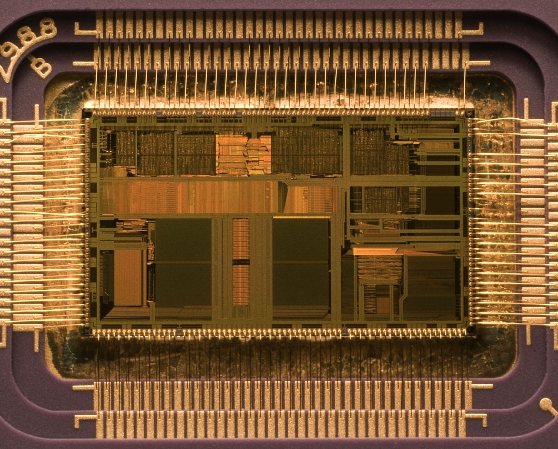

Understanding Semiconductor Yield & Reliability

Semiconductor yield refers to the percentage of functional chips produced during the manufacturing process. It is a critical parameter that directly affects production costs and profitability in the semiconductor industry.

Cost Reduction: Improving yield directly reduces production costs by minimizing the number of defective chips and reducing material waste.

Time-to-Market: Higher yield rates enable faster time-to-market, meeting consumer demand for advanced devices within shorter timelines.

Quality and Reliability: Higher yields correspond to higher-quality chips, ensuring reliable performance and longer lifespan of electronic devices.

Automation and Machine Vision Technology

World is growing at a fast pace. Automation is the best way for your business to achieve better output and quality products

AI Empowering Tomorrow

Highly efficient machine learning models by experienced engineers, powering the future, to a faster and easier automation implementation

Address:

37 Persiaran Mutiara 2, Pusat Komersial Bandar Tasek Mutiara, 14120 Simpang Ampat, Pulau Pinang, Malaysia.

Tel:

+604-5269151